Tip of the Day 86: V->P Transfer Ends Fill

Recently I got a call from a customer that had a fill volume set properly (auto or manual) in order to get good viscosity, fill time and other sequencing information. But Machine Sequence / Fill signal insisted on going off earlier than the fill volume he had set. All the sequence inputs were correct, the Seq. Module Input / First Stage signal went off at the right time etc.

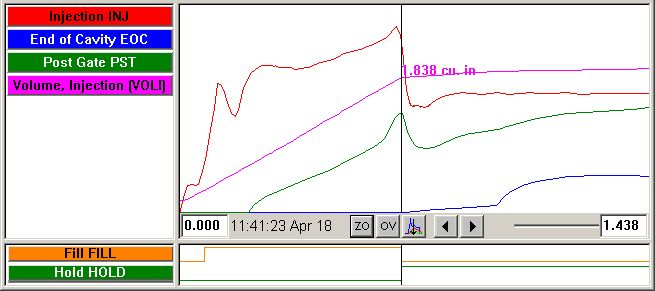

This is what he expected to see. Note that this is a two stage process so V->P transfer would not normally be active. Fill volume is set at 1.838 cu. in.

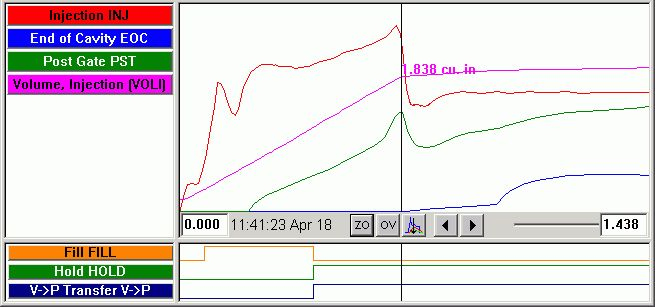

Here is what he actually saw. You can see that V->P transfer was active and firing earlier than the fill volume he had set. But the machine was running at two-stage process with position transfer and was not using the external V->P transfer from the eDART.

Discussion

The eDART thinks that if it has commanded the transfer to occur then this must end fill. It assumes that the signal is hooked up and being used. It assumes that here can be no fill velocity (“V” in “V->P”) after transfer to pressure. So it sets the Machine Sequence / Fill off as soon as the V->P output goes on. In this case it was too early because the “V to P Transfer” tool had an early volume or time control set up. The machine was set to transfer on its own position control and was ignoring external transfer.

Moral of the story: When a process is running with machine controlled transfer turn off the controls on the V to P Transfer tool or drag it off of the current workspace in the Architect. Generally once a process is set up as a machine controlled process you do not need to “attach” the V to P tool to the mold. Conversely, if it IS supposed to run Decoupled 3 then you should attach it and use the external transfer on the machine with appropriately set setpoints.