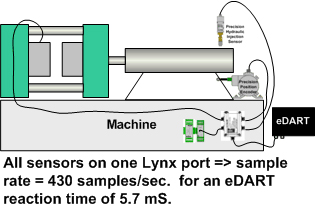

Tip of the Day 111: Splitting eDART Port Load for Speed

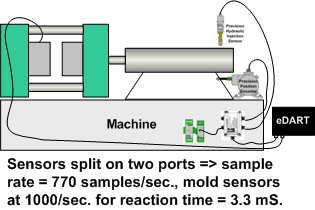

In tip # 110 you probably noticed that the eDARTreaction time depends on the sample rate of all the sensors attached to the Lynx port. We recommend that you split the sensor load between the two Lynx ports on the eDART in order to get the fastest reaction time possible. The sketches below demonstrate this idea based on the sample rate calculations in the spreadsheet in tip # 46 (see latest version on web site).

Another Big Advantage of Splitting Sensor Load: Keeping the “Cushion” Computation Correct

As you see we suggest splitting the ports between mold and machine sensors. The other good reason for this is that the operator disconnects and reconnects mold sensor cables with every mold change. In the process of breaking the data stream the sensors have to re-organize themselves in the data stream, like a chain of elephants after a stampede. If the stroke encoder (LE-R-30) is on the same port where the mold sensors are swapped it can loose power momentarily or reset itself. Then, if you have used “Set Screw Bottom” on the eDART it has forgotten where screw bottom is. When it reconnects itself the eDART can still work stroke and volume but can no longer figure out the correct cushion.