Tip of the Day 127: Failsafe (Good Sorting Output) Required for Missing Values

Recall from tips of the day #’s 1 and 2 that you should use Sorting Output / Good Control for all applications in which you are not doing 3-way sorting. This technique ensures that if anything is wrong or missing the parts will not be shipped. Here is an additional point to reinforce the importance of this method.

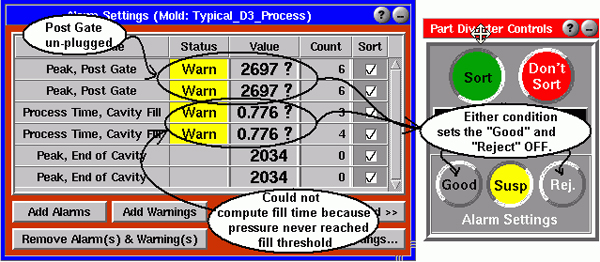

When the eDART™ cannot compute a summary value that is used in the alarm settings then it places a question mark on the value and calls it a warning (the word “Warn”). This turns the Good Output OFF but does NOT turn the Reject output on.

Why would the eDART not compute a value? One of the most common reasons is that the sensor cable was not plugged in making the inputs invalid due to a “No Reply”. It may also not compute a value if the necessary data to compute it are not found. For example, if you set an alarm on Process Time / Cavity Fill and the pressure in the cavity never reaches the fill threshold then the eDART cannot compute a fill time (see tips # 19 and 99). Rather than filling in an arbitrary number the Alarm Settings tool records it as a warning and the Diverter Controls counts it as “Suspect”.

All of the above cases above produce a “Suspect” part that turns off both Good and Reject outputs.

Therefore, if you want no suspect parts shipped you must only use the Good output for sorting.