Tip of the Day 39: How Values Depend on it

We have covered most of the ways that the eDART can get its Machine Sequence information. The reason for getting the sequence right is so that the eDART will calculate accurate summary values. One of the most important values calculated is Effective Viscosity during fill. This is generally a variable over which you have no control but is a huge factor in analyzing problems. Most of the other summary values record how the machine is working. A few in-cavity variables (e.g. cavity fill time) relate to the start of fill sequence.

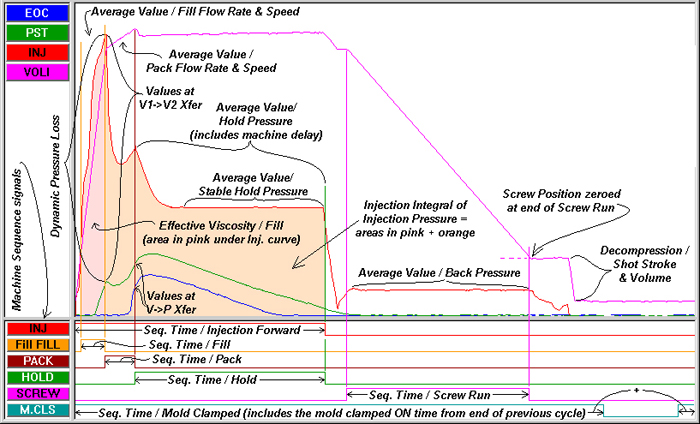

I have tried to represent the more important summary values computed in the graph below.

Here is the same information from the graph but shown in a list (plus a few more). These are the more important summary values that depend on Machine Sequence signals (the sequence signals computed by the sequencer, not those directly input from the machine).

Machine Sequence / Injection Forward

- All Injection Integrals

- Sequence Time / Injection Forward

- Gate Seal

- Mold Deflection Pressure

Peaks on cavity pressures are normally computed only during injection forward (unless selected otherwise in the Sequence Settings “Other” tab).

Machine Sequence / Fill

Effective Viscosity / Fill (both start and end of fill)- Fill Shear Rate / Inverse Fill Time

- Sequence Time / Fill Time

Process Time / Cavity Fill depends on the start of fill being correct

Fill and Pack Time and Fill and Pack Integral depend upon the start of fill being correct

Average Values for Fill Flow Rate (volumetric) and Fill Speed (linear)

Process Metric / Match Error (depends on correct fill start; currently generated by Process Match Meter)

Dynamic Pressure Loss (needs end of fill to know when to compute pressure loss)

Values at V1->V2 Xfer (if a 3-stage process).

Value at V->P Xfer. if it is a 2-stage process (no pack)

Machine Sequence / Pack

Average Values for Pack Flow Rate (volumetric) and Pack Speed (linear)- Sequence Time / Pack Time

Value at V->P Xfer. (also works in 2-stage process if there is no pack)

Machine Sequence / Hold

- Sequence Time / Hold Time

- Average Value / Hold Pressure

- Average Value / Stable Hold Pressure

Machine Sequence / Screw Run

- Correct zeroing and direction of the stroke sensor which in turn affect Machine Sequence / Fill and all that follow from it.

Sequence Time / Cycle Time if there are no other sequence signals after (such as Mold Clamped)- Sequence Time / Screw Run

- All Cycle Integrals (unless the Sequence Settings “Other” tab is used to set a fixed integration limit)

- Average Value / Backpressure

Decompresssion / Shot Volume and Decompression / Shot Stroke

Machine Sequence / Mold Clamped

- Sequence Time / Cycle Time

- Sequence Time / Mold Clamped

Cycle Integrals if time before mold clamped is set up for the integration limit in the Sequence Settings “Other” tab