Tip of the Day 96: Inject Enable

In such documents as our Valve Gate control we encourage the use of the “Inject Enable” feature on the eDART. This tip is to clear up some confusion about its purpose and function.

The short story is that “Inject Enable” is a relay contact closure from the eDART (OR2 output) that stays closed as long as everything is operating properly. If something fails the output opens. The machine should recognize this contact opening and stop to prevent any damage.

How do I set it up?

Select an OR2 output on the eDARTs Sensor Locations page and define it as Control Output / Inject Enable. This definition is saved with the machine so you only have to set it up once per machine.

When does the Output Operate?

If you have defined an Inject Enable OR2 contact then the contact stays closed until one of the following occurs:

- A sensor being used for control (valve gate, v->p transfer, basic 3-stage control) sends a signal that it has failed or stops communicating the eDART immediately opens the Inject Enable contact.

- Any modules that are used for control or sequencing cease to communicate.

- The Inject Enable OR2 itself is disconnected

- The power to the eDART is turned off.

- Note that if you are using a control tool such as V->P transfer the Inject Enable output only comes on after the control tool is up and running.

How Do I turn the Inject Enable On again to let the machine run?

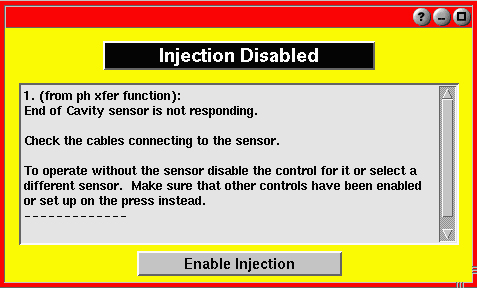

- First read the message that pops up like this example:

- If the controlling sensor begins to communicate again (e.g. replacing a cable) or the failure indicator goes away the eDART will turn the Inject Enable on automatically and the message will disappear on its own.

- If the sensor is truly gone you can turn off the control that uses it (e.g. un-tick the box for control in V->P Transfer) and run with machine control. You could also use a different sensor for control.

- If you wish to try to continue running without making any control changes you can click “Enable Injection”. This function has security in case you don’t want untrained operators to enable injection and continue running.

If you click “Enable Injection” be sure you have backup control on the machine in order to run without damage.

Why Should I Use Inject Enable?

In a complex control system that depends on many sensors and wires we recommend that you use Inject Enable to prevent damage due to loss of control. Suppose, for example, a cavity pressure sensor cable gets pinched and that sensor is supposed to close one gate and open another at a specific setpoint. With the sensor gone the valve gate control would never close the first gate. This could overfill and severely flash one cavity.

Choosing to get the feature programmed into the machine and using it is simply a matter of balancing risk. If your eDART installation (power and wiring) is secure and guarded and you have good backups set on the machine control you can reduce the risk of not using it. However if a broken sensor or a de-powered eDART can cause thousands of dollars of damage to a mold (as I just heard recently) then by all means use Inject Enable.