Tip of the Day 115: Beware the Locked Screw

(and shun the frumious bandersnatch)

Let us once more fortify this idea: Know your machines when making fill-only parts to build or check decoupled processes.

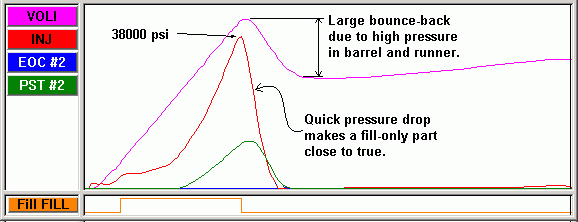

Generally when you have turned off hold using either a zero pressure or zero time setting (or both) the screw will bounce back at transfer. This is acceptable because the intent is to make a fill-only part that will show you as close as possible where the flow front was located when the machine transferred (or slowed to V2 in decoupled III).

Here is a shot from a thin-wall ( .030″ thick) part running polycarbonate. In this case the bounce-back is quite dramatic. But the flow front stopped (nearly) at transfer and that is what we want.

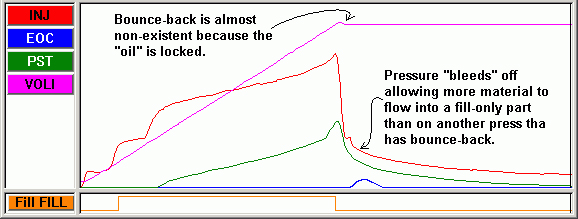

Here is an example of a machine that does NOT bounce back. Instead, by just setting hold pressure to zero it switches of the valve (or the “virtual valve” in an electric) and the oil can’t flow either way. So the screw essentially locks in place. The pressure built up during the speed phase (filling) continues to fill the part because the press does not allow it to dissipate.

On the above press you could get rid of the residual pressure by setting the hold time to zero. Of course you would need to be concerned about mold clamped and cycle time as described in tip #112 and would need to add screw delay accordingly (when making fill-only parts).

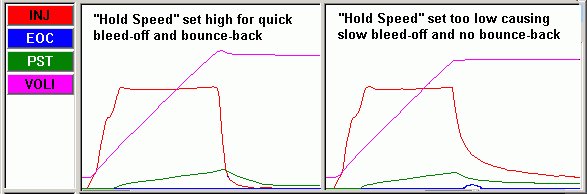

Some machines have a “hold speed” setting that you can adjust to try to dump the pressure.

Of course if you want a quick transfer to hold it would be wise to make sure that the “hold speed” setting does not restrict transfer response even during normal cycles.

We could struggle eternally with whether you might or might not want the flow from the melt decompression included in the fill-only part. When setting up decoupled processes it is important that the fill-only parts are made the same way on different machines in which a mold runs. Otherwise you might get the transfer (or slow-down) position set incorrectly due to different controller behavior.

Once more, then, the key concept when making fill-only parts is…?

(it’s a quiz, folks).